Turbo Energy Private Limited (TEL) was incorporated on 3rd May 1982, as a joint Venture between Brakes India Limited, Sundram Finance Limited and BorgWarner Turbo System (formerly known as KKK - Germany).

The company is engaged in manufacture of turbochargers as well as parts of turbocharger. The products of the company find application in automobile, industrial and marine segments. The Company is a Part of TVS Group.TEL has achieved a sales turnover of Rs.7.8 billion in FY 2013-14.

TEL has been able to achieve customer satisfaction by being able to provide products and services of high quality at globally competitive prices.

For More Information Visit Offical Site →In exhaust gas turbo charging, part of exhaust gas energy, which would normally be wasted is used to drive a turbine. The turbine shaft is connected to a compressor, which draws in combustion air, compresses it, and then supplies it to the engine. The increased air supply enables more fuel to be burnt; hence the engine develops higher power. Increased air availability improves combustion of fuel, thus leading to lower fuel consumption and less emission.

The advantages of modern turbocharged engine, compared to naturally aspirated engines of identical power output are as follows:

As a result, turbochargers contribute significantly to the protection of the environment and the better utilization of energy resources.

A turbocharger comprises of a compressor and a turbine. The turbine and compressor wheels are mounted on a common shaft. This sub-assembly is known as the rotor. The rotor is supported by journals housed in the central housing. The turbocharger turbine consists of the turbine wheel and turbine housing. The engine exhaust gases are directed to the turbine wheel via. Turbine housing. The energy available in the exhaust gas is converted into kinetic energy by the turbine housing and is used for driving the turbine wheel and compressor wheel as both are mounted on common shaft.

The compressor consists of the compressor wheel and compressor housing. Whenever the compressor wheel rotates, the air is drawn axially, and delivered radially at a higher pressure to the intake manifold. Increase in pressure also results in increase in temperature. To reduce the compressed air temperature, some of the turbocharged engines use an after cooler.

For reasons of improved drivability, a smaller turbine size is chosen such that sufficient boost pressure is available at low speeds. In such cases, part of the exhaust gas is by-passed once the required boost pressure is reached. This is achieved by opening a valve operated by a spring-loaded diaphragm (actuator assembly).

Basic Turbocharger without boost control. Mainly used in Industrial and off-highway engines and in some commercial vehicles.

Turbocharger with Max. boost pressure control. Currently used in Passenger cars, M U Vehicles and commercial vehicles.

The Engine exhaust manifold and turbine housing of the turbocharger is made in single piece. This eliminates joints and facilitates ease of assembly onto the engine.

Variable Turbine Geometry (VTG) Turbocharger provides boost on demand due to its unique control mechanism. Mainly used in new generation Passenger cars and M U Vehicles meeting BS IV and above Emission norms.

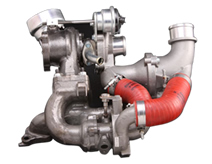

Regulated two stage Turbocharger (R2S), this system uses one low pressure turbocharger and one high pressure turbocharger i.e. two turbocharger for one engine to obtain high density power. This system offers possibility in downsizing the engine to meet future Emission norms while meeting the customer drivability requirements.

Gasoline (Petrol) Turbocharger is similar to that of diesel engine turbocharger in its working. However, the materials used are special and will have additional features like water cooled bearing housing and recirculation valve to meet specific gasoline engine operating requirements.